Tips to consider when purchasing closures

When selecting Closures, pipeline operators should consider safety and performance factors. The TDW D2000 Closures with the ProSeries™ Advantage is the safest, most trusted closure on the market.

“Imitation is the sincerest form of flattery that mediocrity can pay to greatness.”

Don’t compromise safety and performance by settling for imitations. When it comes to closures, cutting corners isn’t an option. The safety of your crews, the integrity of your pipeline, and the efficiency of your operation all hinge on choosing the right product.

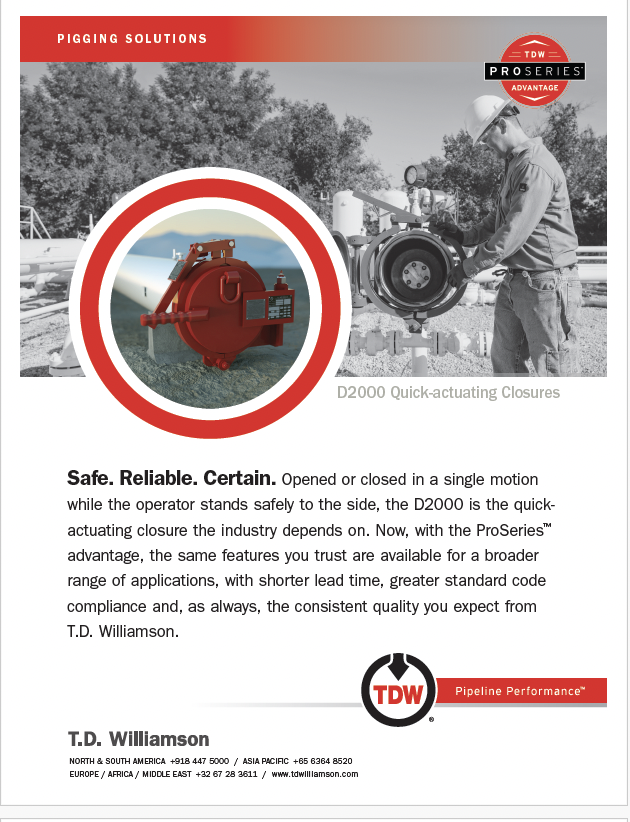

TDW D2000 ProSeries Closure

TDW’s D2000 ProSeries closures are backed by more than 100 years of engineering expertise, field experience, and continuous innovation.

When you invest in the D2000 ProSeries, you’re not just buying a closure—you’re choosing the best-in-class solution backed by a manufacturer who will be here for the lifetime of your pipeline.

the manufacturer

Proven track record – Does the manufacturer have decades of field-proven reliability, or are they new to the market? TDW closures have been rigorously tested and trusted by operators worldwide for generations.

Life cycle support – A closure is only as good as its support. Look at availability of parts, repair services, and consumables like O-rings and Pressure Warning Locks (PWLs). TDW ensures long-term support for every component.

See the D2000 Closure in action

SAFETY FIRST

Operator opening TDW D2000 Closure out of the danger area

The primary question: Does the design keep the operator out of the danger zone?

Operator positioning – With the D2000, operators can safely open the closure from outside the direct line of danger.

Pressure Warning Locks – Placement matters. PWLs located in the 12 o’clock position are less likely to collect debris than those on the door face. The D2000 design directs any retained pressure safely away from the operator.

TDW D2000 Proseries Closure

Durability and spares – Unlike metal-to-metal seals that wear out quickly, TDW’s PWLs are supported with readily available O-rings and replacement parts, ensuring reliability and uptime.

Design AND FEATURES that matter

Simplicity of operation – Fewer moving parts mean fewer failure points and easier maintenance.

Ease of alignment – A single pivot point makes aligning the door with the collar straightforward and efficient.

Clamping surface design – Closures with parallel, non-wedging clamp-rings eliminate force transfer to holding components, reducing wear compared to tapered, wedging surfaces.

O-Ring LOCATION and performance

Sealing performance is critical, and O-ring placement makes a big difference.

D2000 Proseries O Ring

Protected placement – O-rings positioned on the external outer edge of the collar are less likely to be damaged during pig loading or removal, and they’re better protected from debris.

Leak prevention – Properly compressed O-rings perform even at low pressure, reducing leak risks.

Material options – TDW offers multiple O-ring materials to suit varying operating conditions, giving operators flexibility and reliability.

TDW closures are there for the lifetime of your pipeline.

At Kerr Engineered Sales Company, we know closures inside and out. For over 73 years, we’ve been helping operators make the right decisions for pipeline safety and efficiency. As TDW’s representative since 1952, we stand firmly behind their products and their commitment to excellence.

CLOSING TDW D2000 CLOSURES

The D2000 quick-actuating closure combines operator safety with ease of operation. After depressurization, closing operations are performed in a fast, single motion. Here’s a quick guide to closing procedures.

TDW PIGGING INSIGHTS - Episode 6

A quick guide to closing and maintaining the D2000 Closure.

D2000 Quick-Actuating Closure

The D2000 quick-actuating closure combines operator safety with ease of operation. After depressurization, opening and closing operations are performed in a fast, single motion, with the operator standing safely to the side. The D2000 closure maximizes efficiency and reduces both, personal operator risk and company operational cost.

CLOSING PROCEDURES

Before closing, inspect, clean, and lubricate the O-Ring on the barrel collar, including the O Ring grooves and sealing surfaces

Push the door firmly shut with no gap between the door face and hub face.

Pull down on the clamp ring handle to close the door.

Install the pressure warning lock screw, make sure it is not cross threaded.

Hand tighten the pressure warning lock screw and then add about one eighth of a turn with a wrench. Do not over tighten.

MAINTENANCE TIPS TO BE DONE REGULARLY

Lubricate all the pivot point on top of the clamp ring assembly, front and back, as well as door hinge, top and bottom

Keep all the exterior surfaces painted to prevent rust

Other blogs you may be interested in:

If you have questions, please contact the Kerr Engineered Sales Company who are also available for team presentations, lunch and learns and customer visits.

OPENING TDW D2000 CLOSURES

The D2000 quick-actuating closure combines operator safety with ease of operation. After depressurization, opening and closing operations are performed in a fast, single motion. Here’s a quick guide to opening the closure.

TDW PIGGING INSIGHTS - Episode 5

A quick guide to opening and maintaining the D2000 Closure.

D2000 Quick-Actuating Closure

The D2000 quick-actuating closure combines operator safety with ease of operation. After depressurization, opening and closing operations are performed in a fast, single motion, with the operator standing safely to the side. The D2000 closure maximizes efficiency and reduces both, personal operator risk and company operational cost.

OPENING

To safely open the TDW D2000 clamp ring closure door, follow these procedures:

Isolate the vessel from line pressure, bleed the pressure to 0 psig and drain.

Always stand on the side of the closure that is opposite the door hinge.

Open the pressure warning lock by turning the screw counterclockwise. If there is still gas in the line, tighten pressure warning lock and continue to bleed pressure until 0 psig, then continue procedure again.

Inspect the pressure warning lock, O-Ring and the bushing.

Lift the clamp ring handle and put the pressure warning lock in the hole furthest to the right.

Clean and lubricate the interior surface of the clamp ring.

MAINTENANCE TIPS TO BE DONE REGULARLY

Lubricate all the pivot point on top of the clamp ring assembly, front and back, as well as door hinge, top and bottom

Keep all the exterior surfaces painted to prevent rust

Check out our Pig Resource page.

If you have questions, please contact the Kerr Engineered Sales Company who are also available for team presentations, lunch and learns and customer visits.

Tie-In Solution for Pigging-Compatible Natural Gas Pipelines

An elegant tie-in solution was necessary for maintaining the piggability of main pipelines. Two 12-inch natural gas lines needed to be connected to a new well site near Pittsburgh. An innovative solution was used with TDW fittings and pig guide bars.

When maintaining the piggability of main lines was crucial, an elegant tie-in solution WAS necessary.

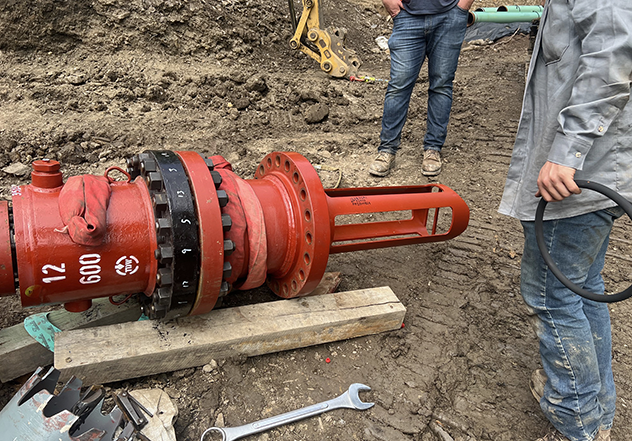

The job site with the two 12-inch x 12-inch 3-WAY™ Tee Fittings

Project Overview

A new natural gas well was being completed near Pittsburgh, necessitating the connection of two 12-inch lines from the well site to two 12-inch main lines. The 12-inch main lines needed to remain piggable.

Design & IMPLEMENTATION

To meet these requirements, an innovative solution using TDW 12-inch x 12-inch 600 class 3-WAY™ Tee Fittings with LOCK-O-RING® and pig guide bars was used. The LOCK-O-RING® completion plug features an interlock system that helps eliminate potential leak paths and ensures proper seating. The implementation process included:

Fitting Installation: The 3-WAY™ Tee Fittings were welded onto the 12-inch main lines.

Pipeline Connection: The 12-inch pipes with valves were welded to the 12-inch outlets on the fittings.

Hot Tapping: TDW service technicians performed two 12-inch Hot Taps.

Completion Plug Setting: The completion plugs with pig guide bars were set into the fittings by the TDW service technicians.

One of the completion plugs with pig guide bars

This approach allowed for the seamless integration of the new well site while maintaining the piggability of the main lines. By utilizing TDW's advanced fitting and plug technology, the tie-in solution not only met the immediate operational needs but also provided long-term reliability and safety for the pipeline system.

Kerr Engineered Sales Company has been representing leading pipeline repair and performance companies in Eastern US since the company was founded in 1952. Seventy two years later, the company remains a family business serving customers with the highest quality service and expertise.

Our application specialists at Kerr Engineered Sales Company are also available for demonstrations, team presentations, lunch and learns and customer visits.