OPENING TDW D2000 CLOSURES

The D2000 quick-actuating closure combines operator safety with ease of operation. After depressurization, opening and closing operations are performed in a fast, single motion. Here’s a quick guide to opening the closure.

TDW PIGGING INSIGHTS - Episode 5

A quick guide to opening and maintaining the D2000 Closure.

D2000 Quick-Actuating Closure

The D2000 quick-actuating closure combines operator safety with ease of operation. After depressurization, opening and closing operations are performed in a fast, single motion, with the operator standing safely to the side. The D2000 closure maximizes efficiency and reduces both, personal operator risk and company operational cost.

OPENING

To safely open the TDW D2000 clamp ring closure door, follow these procedures:

Isolate the vessel from line pressure, bleed the pressure to 0 psig and drain.

Always stand on the side of the closure that is opposite the door hinge.

Open the pressure warning lock by turning the screw counterclockwise. If there is still gas in the line, tighten pressure warning lock and continue to bleed pressure until 0 psig, then continue procedure again.

Inspect the pressure warning lock, O-Ring and the bushing.

Lift the clamp ring handle and put the pressure warning lock in the hole furthest to the right.

Clean and lubricate the interior surface of the clamp ring.

MAINTENANCE TIPS TO BE DONE REGULARLY

Lubricate all the pivot point on top of the clamp ring assembly, front and back, as well as door hinge, top and bottom

Keep all the exterior surfaces painted to prevent rust

Check out our Pig Resource page.

If you have questions, please contact the Kerr Engineered Sales Company who are also available for team presentations, lunch and learns and customer visits.

Tie-In Solution for Pigging-Compatible Natural Gas Pipelines

An elegant tie-in solution was necessary for maintaining the piggability of main pipelines. Two 12-inch natural gas lines needed to be connected to a new well site near Pittsburgh. An innovative solution was used with TDW fittings and pig guide bars.

When maintaining the piggability of main lines was crucial, an elegant tie-in solution WAS necessary.

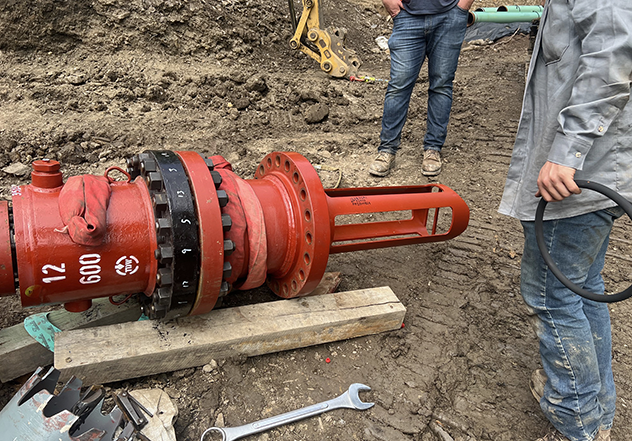

The job site with the two 12-inch x 12-inch 3-WAY™ Tee Fittings

Project Overview

A new natural gas well was being completed near Pittsburgh, necessitating the connection of two 12-inch lines from the well site to two 12-inch main lines. The 12-inch main lines needed to remain piggable.

Design & IMPLEMENTATION

To meet these requirements, an innovative solution using TDW 12-inch x 12-inch 600 class 3-WAY™ Tee Fittings with LOCK-O-RING® and pig guide bars was used. The LOCK-O-RING® completion plug features an interlock system that helps eliminate potential leak paths and ensures proper seating. The implementation process included:

Fitting Installation: The 3-WAY™ Tee Fittings were welded onto the 12-inch main lines.

Pipeline Connection: The 12-inch pipes with valves were welded to the 12-inch outlets on the fittings.

Hot Tapping: TDW service technicians performed two 12-inch Hot Taps.

Completion Plug Setting: The completion plugs with pig guide bars were set into the fittings by the TDW service technicians.

One of the completion plugs with pig guide bars

This approach allowed for the seamless integration of the new well site while maintaining the piggability of the main lines. By utilizing TDW's advanced fitting and plug technology, the tie-in solution not only met the immediate operational needs but also provided long-term reliability and safety for the pipeline system.

Kerr Engineered Sales Company has been representing leading pipeline repair and performance companies in Eastern US since the company was founded in 1952. Seventy two years later, the company remains a family business serving customers with the highest quality service and expertise.

Our application specialists at Kerr Engineered Sales Company are also available for demonstrations, team presentations, lunch and learns and customer visits.

NEW TDW THREAD-O-RING™ FITTING

The NEW 3-WAY THREAD-O-RING ™ is the same great TDW fitting with an added outline for welded branch connections. Get the fittings you need when you need them.

get the fittings you need when you need them

The NEW 3-WAY THREAD-O-RING™ is the same great TDW fitting with an added outlet for welded branch connections. The fittings are available in 1-inch; 1 1/4-inch and 2-inch sizes.

Pipe type: carbon steel, stainless steel, aluminum

1480 pressure rated

Compatible with existing TDW equipment

Best in market lead times in the industry

Kerr Engineered Sales Company has been representing leading pipeline repair and performance companies in Eastern US since the company was founded in 1952. Seventy two years later, the company remains a family business serving customers with the highest quality service and expertise.

Our application specialists at Kerr Engineered Sales Company are also available for demonstrations, team presentations, lunch and learns and customer visits.

TDW Pig Parts - A Guide

TDW Pigs have various components. They come in a multitude of configurations. This blog reviews key parts that you’ll find on pigs and explains some of their uses.

TDW PIGGING INSIGHTS - Episode 4

Overview of TDW Pig Parts and Their Uses

TDW Pig Parts

TDW designs and manufactures an extensive selection of pipeline pigs for specific applications, such as liquids displacement, cleaning, batching, gauging.

Pigs have various components, and each pig comes in a multitude of configurations. This blog looks at some of the key parts that make up a pig and explains the uses of these parts.

pig PArts and their uses

Discs: Are effective at pushing out solids and providing a good support for the pig.

Conical Cups: Provide excellent sealing characteristics, good support and long wear.

Bypass Ports: These allow some of the flow to bypass through the pig and help minimize solid build up at the front of the pig.

Spring Mounted Brushes: Provide a continuous forceful scraping for removal of rust, scale and other build ups on the wall of the pipe.

Circular Brushes: The brushes are bi-directional and can be stacked for scraping for removal of rust, scale and build-ups.

Pit Boss/Pencil Brush: Scrapes deep into pits to remove build-ups.

Gauge Plate: For discovery of deformities/obstructions in the line, also commonly used prior to ILI runs.

Magnets: Pick up ferrous materials and give indications to loose debris in the line.

Learn more about TDW Pigs and Resources

TDW Pig Resource page.

If you have questions, please contact the Kerr Engineered Sales Company who are also available for team presentations, lunch and learns and customer visits.